Advanced Tech Chimneys

Research and Development

The journey of an Oxygenius tech chimney begins in the Research and Development (R&D) department. Here, engineers and scientists collaborate to design innovative chimney systems that meet the specific needs of diverse industries, such as power generation, chemical processing, and manufacturing. Utilizing advanced simulation software and prototype testing, the R&D team ensures that each design maximizes efficiency, durability, and environmental protection.

Material Selection

Once the design is finalized, the next critical step is material selection. Oxygenius places a strong emphasis on sourcing high-quality materials that can withstand extreme temperatures, corrosive environments, and mechanical stress. Stainless steel, titanium alloys, and advanced ceramics are commonly used materials. Each batch of raw materials undergoes rigorous testing to ensure they meet the company’s stringent quality standards.

Precision Manufacturing

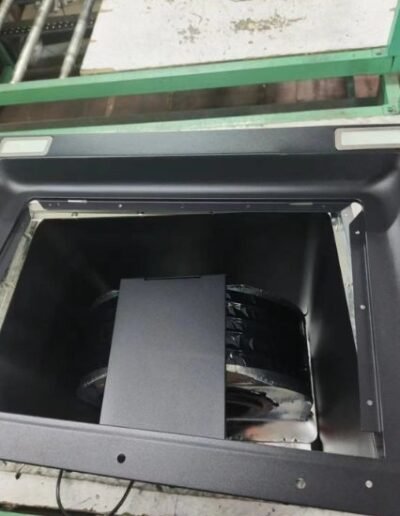

- Cutting and Shaping: The raw materials are precisely cut and shaped using laser cutting and CNC (Computer Numerical Control) machining. This ensures each component fits perfectly with minimal material wastage.

3. Surface Treatment: Post-assembly, the chimney components undergo surface treatment processes, including sandblasting, powder coating, and anodizing. These treatments enhance the chimneys’ resistance to corrosion and wear, ensuring a longer operational life.

Quality Control and Testing

Oxygenius is committed to delivering products of the highest quality. Each tech chimney undergoes a series of rigorous quality control tests:

1.Dimensional Accuracy: Using advanced measuring tools, the dimensions of each component are verified to ensure they meet the design specifications.

3. Performance Testing: The assembled chimneys are subjected to real-world operational conditions in controlled environments to test their performance. Parameters such as temperature resistance, emission control efficiency, and airflow dynamics are meticulously evaluated.

Customization and Integration

Oxygenius understands that each client has unique requirements. The company offers extensive customization options, allowing clients to tailor their tech chimneys to specific operational needs. The engineering team works closely with clients to integrate additional features such as advanced filtration systems, automated monitoring and control systems, and modular designs for easy maintenance and scalability.

Final Assembly and Packaging

After passing all quality control tests, the tech chimneys are moved to the final assembly line. Here, any additional components are integrated, and the chimneys are thoroughly cleaned and prepared for shipment. Each unit is carefully packaged to protect it during transportation, ensuring it arrives at the client’s site in perfect condition.